WE ARE BMP Group!

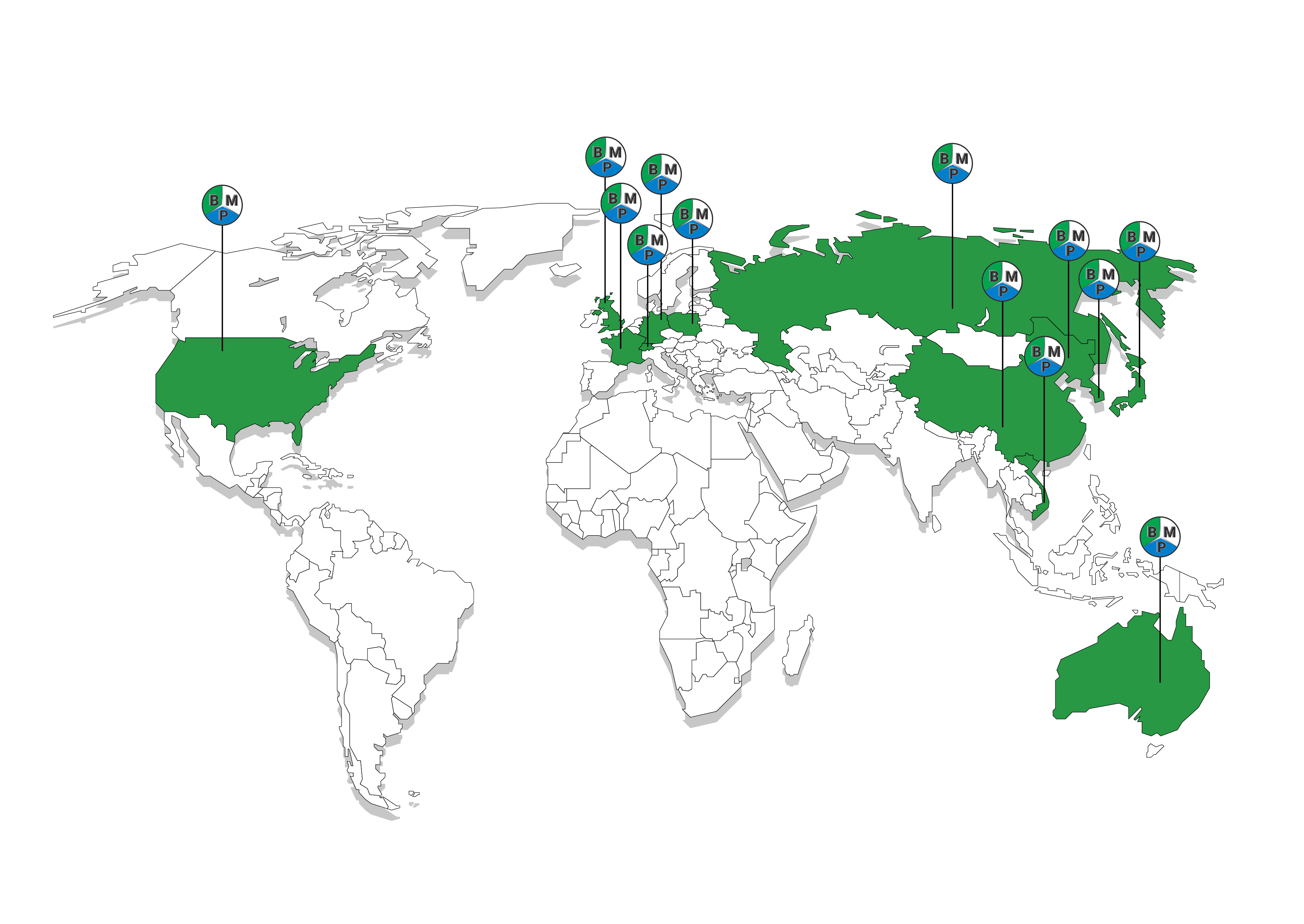

With the mission of “Enhancing corporate brand” supported by complex plastic film packaging products under the International Quality Standards, we strive to develop our great value axis by improving your competitive trends and brand experience in packaging products!

Throughout the 15-year history of developing Binh Minh Packaging Trademark with a long-term strategic vision of modern technology-based packaging, we have always been proactive and flexible in applying the production line from input sourcing to the customer’s final experience. Binh Minh Group is proud to be a pioneer and reliable partner of Vietnamese brands in the packaging field today.