Innovation – Automation – Intelligent Connectivity

At BMP Group, we believe that digital transformation is not just a passing trend; it is a crucial strategy for enhancing operational efficiency, improving competitiveness, and establishing a strong foundation for sustainable long-term growth.

We are actively developing a business model centered around the principle of "Data-Driven Operation," where data is at the heart, AI serves as the tool, and the customer remains the focus.

Operational Automation and

Smart Manufacturing

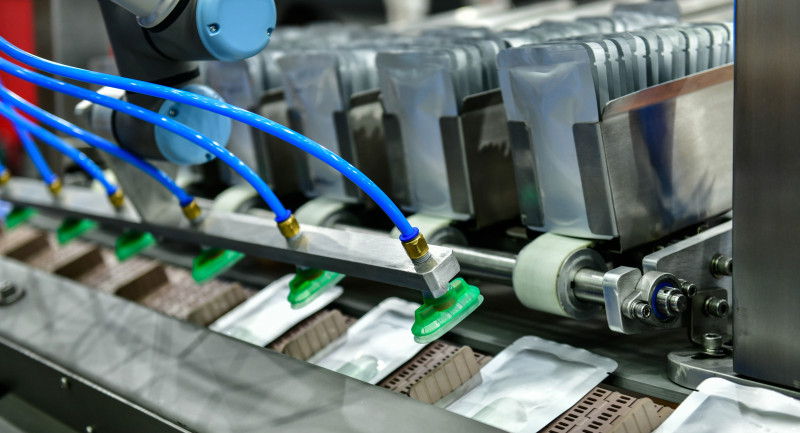

We integrate advanced technology solutions to optimise the entire production process:

- Applying AI and automated control systems to printing, lamination, and film-blowing lines to improve efficiency and reduce technical errors.

- Implementing inline quality control (QC) systems for real-time continuous monitoring.

- Analysing production data to optimize material usage, conserve energy, and reduce waste.

Digitalized Management and

Strategic Decision-Making

BMP operates a unified management system that includes:

- ERP, CRM, and BI platforms that effectively manage finance, inventory, HR, sales, and customer care.

- Real-time data integration across departments such as planning, production, sales, procurement, and quality.

- AI-driven data analysis for forecasting output, optimizing order fulfillment, and managing logistics costs, enabling quick, accurate, data-based decisions.

Customer and Partner Engagement

via Digital Platforms

We accelerate digital transformation across the entire customer journey by:

- Implementing real-time tracking systems for monitoring production and order progress.

- Enhancing our digital presence through our website, LinkedIn, email marketing, and customer portals.

- Developing a vendor portal—a shared data platform with suppliers to ensure transparency and efficiency in our supply chain.

Building Digital competency

across the workforce

Digital transformation begins with people. BMP is committed to enhancing its workforce's skills through:

- Internal training: digital technologies, software usage, and information security.

- Promoting a Digital-First Culture: reducing paperwork, encouraging knowledge sharing, and making data-driven decisions.

- Establishing a Digital Transformation Taskforce: a dedicated team leading the company's digitalization efforts.

AI Camera – Proactive Safety and System Integration

- Facial and license plate recognition, integrated with attendance tracking and behavior monitoring on factory premises.

- Automatic detection of safety violations such as: Not wearing protective equipment, Entering restricted areas, Congregating in restricted zones

- Real-time alerts are sent to safety and management teams.

This solution fosters a proactive safety culture, mitigates risks, and enhances compliance awareness throughout the organization.

System integration – Moving toward a smart factory

All AI modules are seamlessly connected with:

- MES (Manufacturing Execution System)

- ACS (Access Control & Security)

- BI (Business Intelligence Data Center)

This integration brings BMP closer to the Smart Factory model, where all operations are automated, connected, safe, and sustainably managed.