Robust manufacturing capabilities,

consistent quality

With superior production capabilities, a skilled technical team, and advanced printing technology, BMP Group proudly offers high-quality packaging solutions while partnering with clients to enhance brand value and optimize product performance.

Manufacturing capacity and a strategic factory network play a key role in ensuring on-time delivery, cost optimisation, and consistent quality. As one of the pioneers in the packaging industry in Vietnam, BMP Group is proud to own a modern infrastructure system strategically distributed to best serve both domestic and international demands.

BMP currently operates two major manufacturing plants:

- VSIP IIA Industrial Park (Binh Duong): Southern hub for flexible packaging

- Tan Phu Trung Industrial Park (Cu Chi): Logistic gateway of Ho Chi Minh City

With a total manufacturing capacity of 4,200 tons per month, BMP’s network effectively serves the needs of various local and global industries.

Specialization of production

Each plant is strategically designated for:

- Complex flexible packaging: For food, beverages, and pharmaceuticals

- Single-layer PE film: Cost-effective basic packaging

- Kraft paper/pouch packaging: In line with green packaging trends

With well-invested production infrastructure, BMP is ready to partner with domestic and international clients to develop modern, efficient, and sustainable packaging solutions.

BMP invests in modern infrastructure and optimizes its production processes to ensure that all types of packaging—from rollstock to pouch or die-cut lid—meet the highest standards of quality, performance, and precision.

Rollstock film packaging

Application: Designed for automated packing machines used by food, pharmaceutical, and beverage manufacturers.

Process:

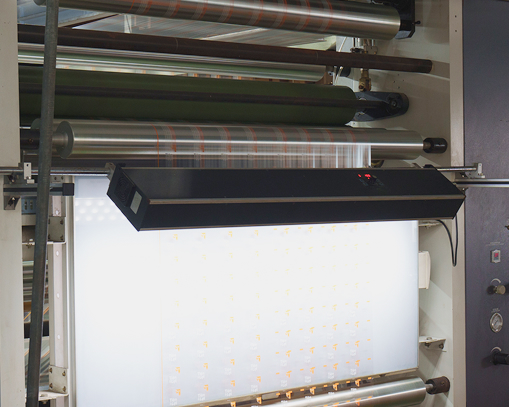

- Printing: Utilizes gravure, offset, or flexo printing based on design, quantity, and material requirements.

- Lamination: Enhances mechanical strength and protects products from moisture, oxygen, and light.

- Slitting: Precision cutting to match customers' packing machine dimensions.

- Packing: Properly packed and stored before shipment.

Pouch packaging

Applications: Zipper bags, stand-up pouches, 3-side seal pouches for coffee, snacks, cosmetics, supplements...

Process:

- Printing: Sharp, vivid printing suitable for materials such as PET, kraft, and OPP....

- Lamination: Enhances moisture resistance, gas barrier, and product protection.

- Pouch Conversion: Finished according to exact size and design: stand-up pouches, spout pouches, zipper bags...

- Packing: Inspected & packed per export standards.

Die-cut Lid Packaging

- Application: Used for food containers, instant noodle cups, paper can lids, plastic jar lids...

Process:

- Printing: Sharp, custom-designed printing suited for aluminium, PET, coated paper...

- Lamination: Increases durability and heat-sealing compatibility with containers.

- Lid Converting: Die-cut into desired shapes.

- Packing: Ensures seamless integration into customers' production lines.

BMP Group is committed to optimising production processes for each packaging line, ensuring high efficiency and compliance with both local and international quality standards such as ISO and BRCGS. For every order, we partner with clients to create truly effective and sustainable packaging.

Equipped with modern machinery and a diverse range of printing technologies, BMP flexibly meets all design, material, and order volume requirements. We invest comprehensively in three core printing technologies: gravure, offset, and flexo printing—each offering unique advantages tailored to customer needs and market trends.

Gravure printing

Advantages:

- High precision, vibrant colours, long-lasting quality.

- Excellent for reproducing complex images, large colour blocks, or gradient effects.

Especially suited for premium packaging requiring large-volume printing.

Applications: Food, beverage, cosmetic packaging, high-end pouches.

Offset printing

Advantages:

Exceptionally sharp images, high resolution, intricate details.

Cost-effective for large print runs with complex designs.

Accurate colour reproduction, ideal for aesthetically demanding prints.

Applications: Paper bag packaging, product labels, paper boxes, catalogs.

Flexo printing

Advantages:

- Eco-friendly technology using water-based inks.

- Capable of printing on recycled materials like kraft, OPP, and mono-material films.

- High-speed printing is ideal for mass production, saving time.

Application: Eco-packaging, kraft pouches, environmentally friendly films.

We are committed to not just printing beautifully – but printing efficiently, greenly, and in line with each client's branding strategy.