BMP GROUP PACKAGING

Product innovation

Partnering with businesses to create quality,

sustainable, and cost-optimised packaging.

sustainable, and cost-optimised packaging.

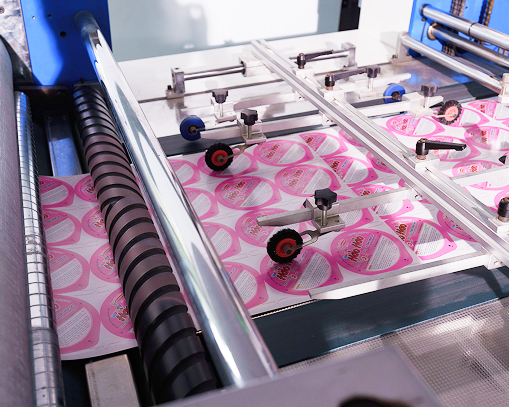

With a mission to partner with businesses in creating high-quality, sustainable, and cost-effective packaging products, BMP provides comprehensive solutions that cover the entire process—from ideation to production, testing, and legal compliance. This approach helps customers accelerate their time-to-market, protect their brand, and strengthen their leadership position.

BMP Group places a strong emphasis on research and development (R&D) to stay ahead of technological trends and advancements in sustainable packaging materials. Our focus is not only on innovation but also on delivering cost-saving solutions, optimizing production, and reducing product costs—enabling customers to sustainably enhance their competitive advantage.

BMP offers intelligent and user-friendly packaging design solutions tailored to the unique characteristics of various industries, including food, beverage, and pharmaceuticals. We always prioritize:

Each packaging design combines technical expertise with emotional appeal, allowing brands to connect effectively with their customers.

BMP’s R&D team frequently evaluates and tests new materials to:

This process provides customers with confidence in both performance and compliance with global export and ESG standards.

With a modern infrastructure and a team of experienced technicians, BMP reduces the time it takes to develop a physical prototype from concept to completion. Our services include:

Each prototype serves as a trial, allowing customers to test functionality before proceeding to mass production.

At BMP, all tests are performed in accordance with international ASTM standards to ensure the durability, safety, and real-world performance of our packaging. Our testing includes:

We operate a cleanroom production area that meets the standards of:

BMP fully complies with strict regulations from:

This is the basis for customers to feel secure when exporting products to international markets.

We offer comprehensive documentation and consulting services to assist our customers in the following areas:

BMP is dedicated to supporting clients throughout the entire process of testing, auditing, and preparing legal documentation for export packaging.

At BMP, every packaging product is inspected according to specific customer requirements and ASTM standards to ensure quality before shipment. Our process includes: